Table of Contents

Transmission Cooling

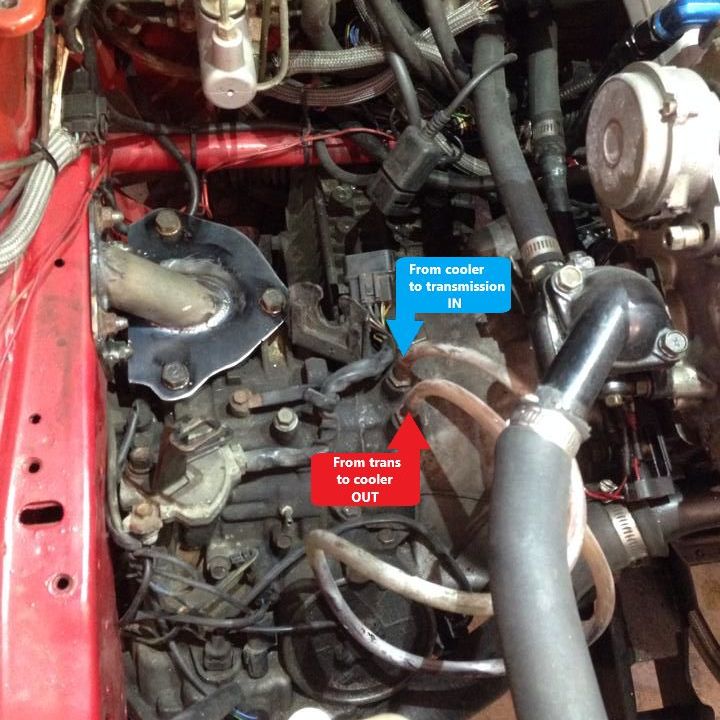

Transmission Cooler Fluid Orientation

The port closest to the firewall is the cooler return. This is where transmission fluid comes from the transmission cooler back into the transmission. The port closest to the radiator of the car is the cooler feed. This is where transmission fluid comes from the transmission and goes to the transmission cooler.

Transmission Cooler In/Out Fitting information

The threading on the transmission for the fittings is M12x1.25. Most replace the OEM with AN fittings that thread right in. -6 seems to be the preferred size.

Transmission Cooler Sizing

This is a tough one. This really depends on the power, load, and many other variables like converter efficiency and so on to determine. You wont find any definite information on cooler sizing. Being that the transmission cooler can be the difference in reliability and rebuilding just use this simple rule. Its better to have and not need then to need and not have. I have personally selected the largest transmission cooler i could get. My selection was the remote mountable Derale 13960. It has a shroud and fan that comes with it. I fully expect this to have no issue maintaining 170 degree outlet temps. A Smaller/cheaper version would be the 13700.

Transmission Temperature Sender Location

A common topic to come up in discussions is where do i need to put my transmission temperature gauge? Well here is the scoop. If you put it before the cooler then your going to be reading the converter outlet temp which is the hottest point. If you put it after the cooler you are reading how well your cooler is doing except that you likely arent reading inlet temp so really your just looking at cooled fluid temp. So the best option would be the hottest point in the circuit which would be before the cooler. This way you know the hottest the fluid gets and the cooler you can keep this the better you will be. Think of it like your cooling system for the engine. The coolant temp sensors are all on on the coolant neck coming off the head. This is the part of the circuit that is hottest as its coming from the engine to the radiator. Same principal with the cooler. Absolute best would be a sensor before and after the cooler. So if you want to do that then by all means do it. Keep in mind that pre-cooler sensors will see temps over 300F and as such you will need a gauge that reads that high. Also just because you bought a gauge that reads that high doesnt mean the sensor will. Ive seen several 350F gauges come with sensors that only read to 290-300 Another option is to use the OEM pan temp or putting an aftermarket sensor in the pan. The oem sensor is just hooked to a dummy light. Also its not recomended to use the pan as a location for the temp sensor as you will not see sudden changes and it will become heatsoaked due to its environment. Stick with the cooler circuit.

Transmission Temperature Gauge

Gauge selection can be tricky. As said above for converter outlet/pre-cooler measurement you need a gauge that reads over 300F. There are a couple options. VDO is probably one of the better options as it goes to 400F. They have two versions. The difference between the two is one is for the included adapters being metric or Standard. part number 310-1071 is STD adapters and 310-1072 is Metric adapters. If you want to monitor pre-cooler and post cooler in one gauge then Spa Technique model DG210DG210 is what you seek. However note this gauges sensor peaks out at 302F. Avoid Maxtow gauges as they are junk.

Gauge selection can be tricky. As said above for converter outlet/pre-cooler measurement you need a gauge that reads over 300F. There are a couple options. VDO is probably one of the better options as it goes to 400F. They have two versions. The difference between the two is one is for the included adapters being metric or Standard. part number 310-1071 is STD adapters and 310-1072 is Metric adapters. If you want to monitor pre-cooler and post cooler in one gauge then Spa Technique model DG210DG210 is what you seek. However note this gauges sensor peaks out at 302F. Avoid Maxtow gauges as they are junk.

Transmission Fluid Temperature Information

OIL TEMPERATURE MEASURED AT CONVERTER OUTLET TO COOLER

300° F= The maximum allowable temperature. This is the recommended place to install a temperature gauge or sensor. Do not allow the converter outlet temperature to exceed 300° F. The temperature at this location will vary significantly because of load, hill climbing, etceteras. If the temperature reaches 300° F, reduce throttle. To lower transmission temperature with transmission in neutral, run the engine at 1,200 RPM for at least 2 - 3 minutes while keeping a close check for signs of engine overheating. A transmission in a heavy throttle, stall condition (a typical situation is rocking a vehicle stuck in mud, sand, or snow), may increase temperature at a rate of 1° degree per second of stall.

OIL TEMPERATURE MEASURED AT OIL PAN OR SUMP

150° F= The minimum operating temperature. Note: It is possible in low ambient temperatures to overcool the transmission with auxiliary oil to air coolers. Oil to water coolers in standard factory radiators will normally not overcool a transmission.

175-200° F= Normal pan oil temperature operating range.

275° F= Maximum allowable oil pan temperature for short durations during long high load scenarios.

300° F= Damage occurs to internal transmission parts, including warpage of metal parts, degradation of clutches, and melting of seals. Transmission oil oxidizes, (forming varnish-like substances causing further clutch slippage and compounding heat build up) and transmission oil life is extremely short.

Transmission Fluid and Filtration

Main article: Transmission Fluid and Fluid Filtration